UNIGRASS provides customers with a comprehensive artificial turf solution, covering installation services for multiple sports venues and landscape turf. We specialize in turf laying for various sports venues such as football, golf, tennis, rugby and padel, ensuring that each project meets international standards and provides excellent sports performance and comfort. In addition, UNIGRASS also provides professional landscape grass installation services to create a natural and green environment for outdoor spaces such as gardens, balconies, public parks, etc. Whether it is a sports venue or landscape design, we are committed to creating long-lasting, beautiful, low-maintenance turf solutions for customers through high-quality turf materials and superb construction technology, enhancing the overall experience and functionality of the space.

Lay a layer of graded crushed stone, usually 5-10cm thick, and compact it again until there is no obvious indentation when stepped on, forming a solid and stable base course.

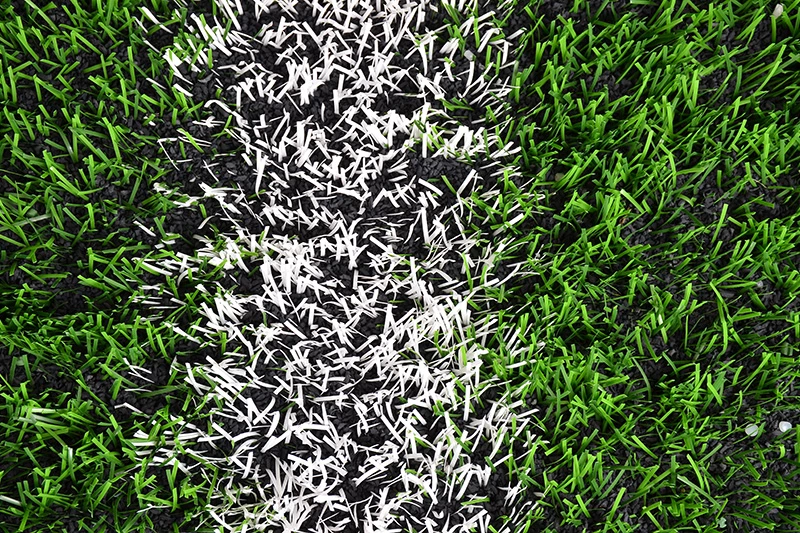

First, unroll the turf rolls sequentially and ensure all grass blades face the same direction. Second, leave a seam overlap, typically 3-5 centimeters. Finally, make precise cuts along the boundaries.

Make sure the selected turf meets national standards to ensure sports performance and safety.

Soil Testing (Optional): Ensure foundation stability and load-bearing capacity through soil analysis.

Site Infrastructure Construction: Includes fencing, traffic safety facilities, and directional signage.

Drainage System: Excavate drainage ditches to prevent water accumulation on the site; a core requirement for outdoor venues.

Subgrade and Surrounding Foundation Treatment: Construction of the subgrade and reinforcement of surrounding areas to ensure structural integrity.

Pedestrian Walkway and Safety Zone Paving: Provide safe passageways for athletes and spectators, including boundary line and bonding layer construction.

Costs depend on the intended use of the field, the sports activities required, and the materials chosen. Professional sports turf suppliers such as UNIGRASS typically offer one-stop services, including:

In addition, different turf fields for different sports will have different cost requirements, mainly depending on the size, shape, turf type and other additional requirements such as markings, equipment and safety areas.

Indoor turf field installation costs: The cost of indoor turf fields will vary depending on the size of the field, lack of drainage systems and the need for dedicated turf. Compared with outdoor fields, indoor fields are protected from weather factors, but unique infrastructure needs need to be considered.

Cushioning Pads: Enhances athletic comfort and reduces the risk of injury.

Artificial Turf Installation: Turf installation, precise line marking, and sports-specific customization.

Infill Material: Most turf systems require infill material to maintain grass fiber shape and drainage; cost varies depending on material grade.

Functional Testing: Testing of particle distribution uniformity and permeability to ensure system durability.

Fence Installation: Secures the field boundaries, prevents equipment/balls from escaping, and protects personnel safety.

Fixed Sports Equipment: Installs essential equipment such as goals and nets according to the type of sport.

The cost of installing artificial turf varies depending on several factors, but generally ranges from a few dollars to $20 per square foot. Generally, the average cost of installation is between $9 and $12 per square foot, and this price usually covers labor and materials. For example, for a small 500 square foot project, the installation cost is about $3,000 to $7,500. The total cost of artificial turf will vary depending on the quality of the turf selected, other materials used, the difficulty of installation, and the installer hired.

For example, if the installation cost is $10 per square foot, the total cost of 1,000 square feet of turf would be $10,000 (including labor and materials). If the installation cost is $5 per square foot, the total cost would be $5,000; if the installation cost is $18 per square foot, the total cost would be $18,000.

In summary, while the size of the area is an important factor in the cost of installing artificial turf, the actual cost will also be affected by factors such as turf quality, installation complexity, and labor costs.

Our whole solution is EU standard. FIP certification is usually applied by client’s side. Our whole solution passed CE certificates, passed EU standard.

Yes, we provide highly customization such as entrance cover, net logo, glass sticker etc.

Yes, we provide padel rackets, padel balls and other related accessories. We also offer logo customization service for the accessories to meet your personalized needs.

Sure. We provide a paper installation manual and 3D video guidance with clear step-by-step instructions. We also offer installation supervision services if needed.

One set is 6 tons, 12cbm.

One 20ft container - 2 sets,

One 40hq container - 4 sets.

We offer three tiers: Standard KDK, Training, and Mondo Pro Competition level—selected based on your club class.

We send courts to your port and you ask local agent to pick up the courts, do the customs and arrange local transportation.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.